iimveliso

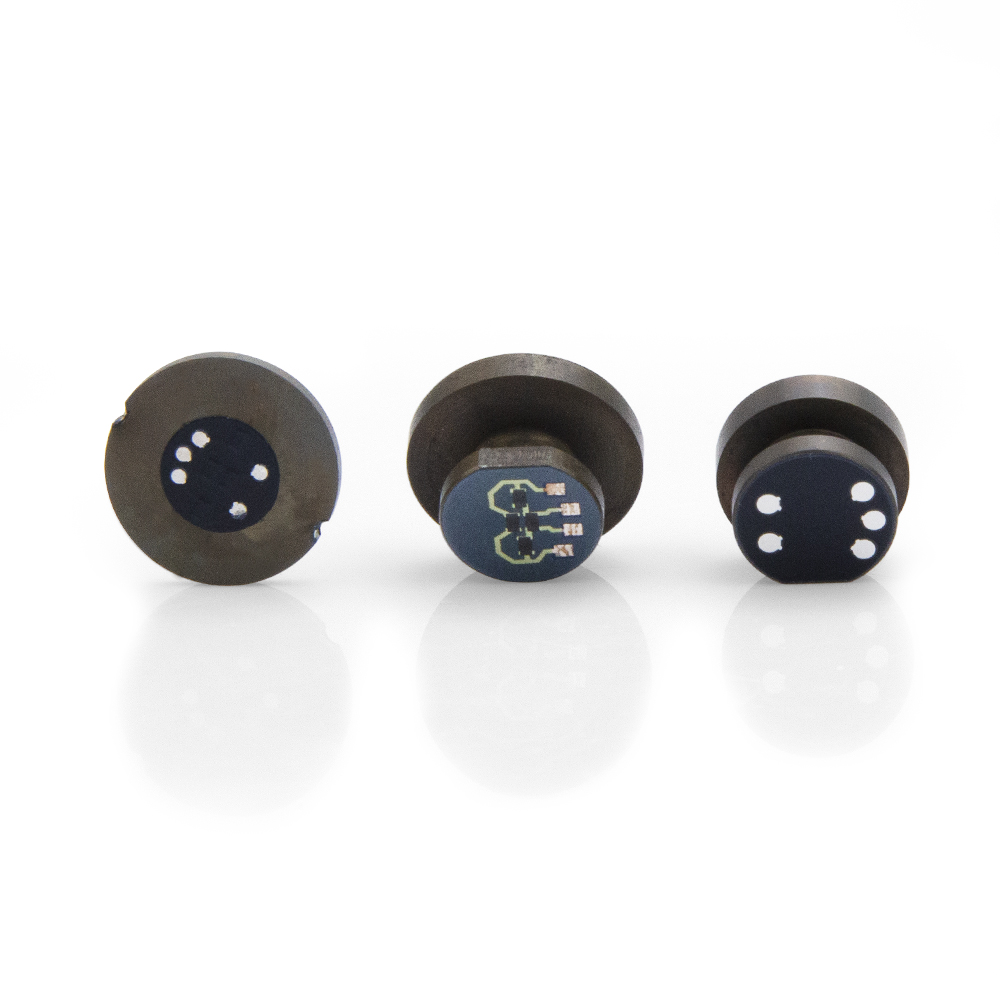

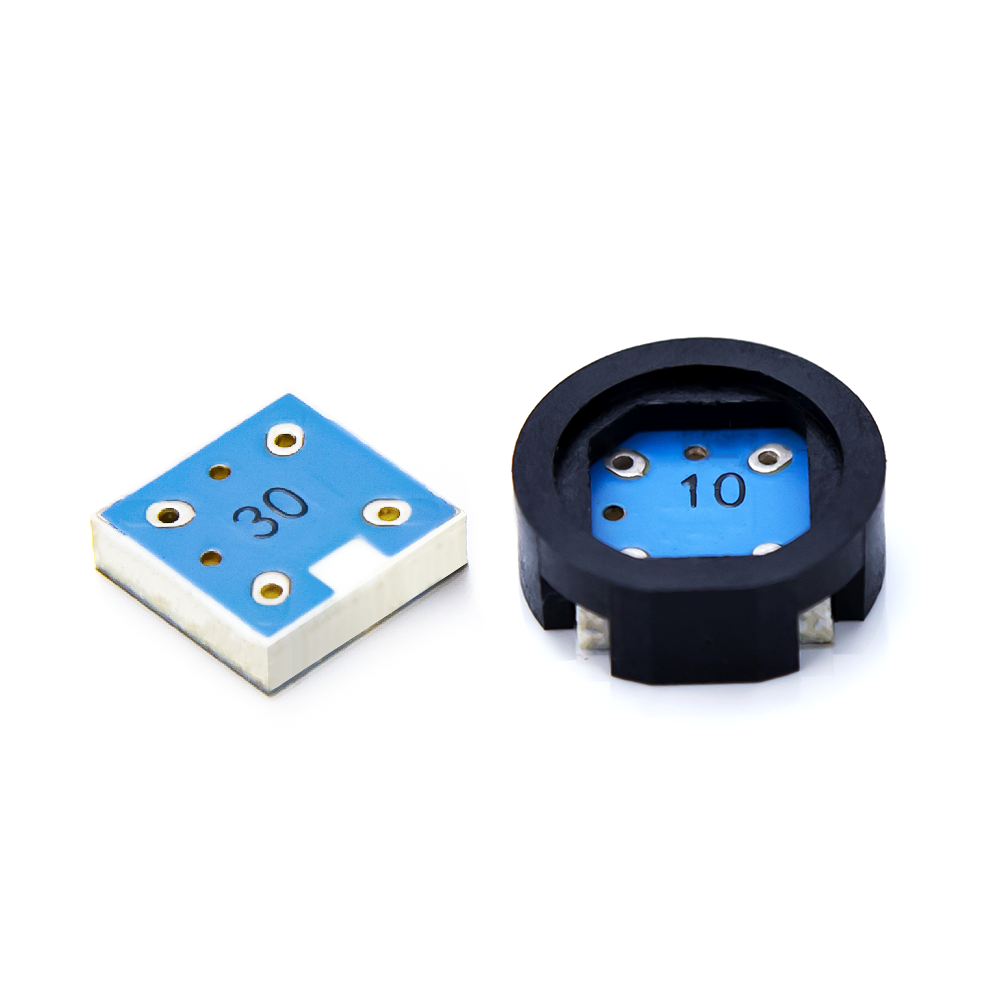

XDB103-9 Series iModyuli yeSensor yoxinzelelo

Iimbonakalo

1. Impazamo: 1% ukusuka ku-0 ~ 8 5℃

2. Uluhlu olupheleleyo lobushushu ( -40 ~ 125 ℃), impazamo: 2%

3. Imilinganiselo ehambelanayo kunye ne-ceramic piezoresistive sensors eziqhelekileyo

4. Uxinzelelo lwe-overload: 200% FS, uxinzelelo lokuqhuma: 300% FS

5. Imo yokusebenza: Uxinzelelo lokulinganisa

6. Indlela yokuphuma: i-voltage output kunye nemveliso yangoku

7. Uxinzelelo lwexesha elide: <0.5%

Usetyenziso oluqhelekileyo

1. Inzwa yoxinzelelo lomoya kwisithuthi sorhwebo

2. I-Oil Pressure Sensor

3. Inzwa yoxinzelelo lwempompo yamanzi

4. Inzwa yoxinzelelo lwe-compressor yomoya

5. Inzwa yoxinzelelo lomoya womoya

6. Ezinye iinzwa zoxinzelelo kwiinkalo zokulawula iimoto kunye nezoshishino

Iimpawu zokusebenza

1. Ngaphakathi kolu luhlu lwamandla okusebenza, imveliso yemodyuli igcina ubudlelwane obulinganayo kunye nomgca.

2. I-Minimum Pressure Offset: Ibhekisela kwi-voltage yemodyuli yemveliso kwindawo yoxinzelelo oluphantsi kakhulu ngaphakathi koluhlu loxinzelelo.

3. IsiPhumo esiPheleleyo: Ichaza i-voltage yemodyuli yemveliso kwindawo ephezulu yoxinzelelo ngaphakathi koluhlu loxinzelelo.

4. Isikali esipheleleyo se-Span: Ichazwa njengomahluko we-algebraic phakathi kwamaxabiso aphumayo kwinqanaba eliphezulu kunye namanqaku aphantsi oxinzelelo ngaphakathi koxinzelelo.

5. Ukuchaneka kubandakanya izinto ezahlukeneyo, kubandakanywa impazamo yomgca, impazamo ye-hysteresis yeqondo lokushisa, impazamo ye-hysteresis yoxinzelelo, impazamo yobushushu obupheleleyo, impazamo ye-zero yobushushu, kunye nezinye iimpazamo ezinxulumene nazo.

6. Ixesha lokuPhendula: Ibonisa ixesha elithathayo ukuze isiphumo sitshintshe ukusuka kwi-10% ukuya kwi-90% yexabiso layo lethiyori.Uzinzo lwe-Offset: Oku kubonisa imveliso yemodyuli emva kokufumana iiyure ze-1000 zoxinzelelo lwe-pulse kunye nokuhamba ngebhayisikile yobushushu.

Ukunciphisa iiparamitha

1. Ukudlulela ngaphaya kowona mlinganiselo uphezulu uchaziweyo kunokukhokelela ekuwohlokeni kwentsebenzo okanye kukonakala kwesixhobo.

2. Igalelo eliphezulu kunye nemisinga yokuphuma inqunywe yi-impedance phakathi kwemveliso kunye nomhlaba kunye nokunikezelwa kwamandla kwisekethe yangempela.

Electromagnetic ehambelanayo EMC

Imveliso ihambelana nezi ndlela zilandelayo zovavanyo lwe-EMC:

I-1) Ukuphazamiseka kwe-pulse okwethutyana kwiintambo zamandla

Isiseko sesiqhelo:I-ISO7637-2: Icandelo lesi-2: Ukuqhutywa kombane okwethutyana ecaleni kweendlela zobonelelo kuphela

| I-Puls No | I-Voltage | Iklasi yoMsebenzi |

| 3a | -150V | A |

| 3b | +150V | A |

I-2) Ukuchasana nokuphazamiseka kwexesha elifutshane kwimigca yesignali

Isiseko sesiqhelo:I-ISO7637-3: “Icandelo lesi-3: Ugqithiso lombane oludlulayo nge-capacitive kunyeukudityaniswa kwe-inductive ngemigca engeyiyo iSupply lines

Iindlela zokuvavanya: Imodi yeCCC : a = -150V, b = + 150V

Imo ye-ICC:± 5V

Imo yeDCC:± 23V

Iklasi eSebenzayo: Iklasi A

3) I-radiated immunity RF immunity-AL SE

Isiseko sesiqhelo:I-TS EN ISO 11452-2 Izithuthi zendlela-Iindlela zovavanyo lwamacandelo ombane Iziphazamiso ezivela kwi-narrowband radiated electromagnetic energy-Icandelo 2: Indawo ebiyelweyo ekhuselekileyo enemigca ”

Iindlela zokuvavanya: I-Antenna ye-Low-Frequency ephantsi: 400 ~ 1000MHz

I-eriyali yokuzuza okuphezulu: 1000 ~ 2000 MHz

Inqanaba lovavanyo: 100V / m

Iklasi eSebenzayo: Iklasi A

4) Inaliti ephezulu yangoku ye-RF immunity-BCI (CBCI)

Isiseko sesiqhelo:I-ISO 11452-4: 2005 Izithuthi zendlela-Iindlela zovavanyo lwamacandelozombane Iziphazamiso ezivela kwi-narrowband radiated electromagnetic-Icandelo 4:Isitofu esikhulu sangoku( BCI)

Uluhlu lokuphindaphinda: 1 ~ 400 MHz

Izikhundla zophando lwesitofu: 150mm, 450mm, 750mm

Inqanaba lovavanyo: 100mA

Iklasi eSebenzayo: Iklasi A

Umsebenzi wokudlulisa kunye nemveliso yeempawu zedayagramu

1 ) Umsebenzi woTshintsho

VPHUMA= Vs× ( 0.00066667 × PIN+0.1 ) ± (impazamo yoxinzelelo × impazamo yobushushu × 0.00066667 × Vs) apho uVslixabiso lombane wobonelelo lwemodyuli, iyunithi yeeVolts.

I-PINlixabiso loxinzelelo lokungena, iyunithi yi KPa.

2 ) Igalelo kunye nemveliso yeempawu zomzobo(VS=5 Vdc , T =0 ukuya ku-85 ℃)

3) impazamo yempazamo yobushushu

Qaphela: Impazamo yempazamo yobushushu iphakathi kwe -40~0 ℃ kunye ne 85~125 ℃.

4) Umda wempazamo yoxinzelelo

Imilinganiselo yeemodyuli kunye neenkcazo zephini

1 ) Umphezulu woluvo loxinzelelo

2) Izilumkiso zoSetyenziso lweChip:

Ngenxa yenkqubo yokwenziwa kwe-CMOS ekhethekileyo kunye nokupakishwa kwesivamvo esiqeshwe kwisijikelezo somoya wetshiphu, kubalulekile ukunqanda umonakalo onokwenzeka kumbane ongatshintshiyo ngexesha lokudityaniswa kwemveliso yakho.Gcina ezi ngqwalasela zilandelayo engqondweni:

A) Misela imeko-bume yokhuseleko echasene ne-static, egcwele i-anti-static workbenches, i-table mats, i-floor mats, kunye ne-wristbands yomsebenzisi.

B) Ukuqinisekisa ukusekwa kwezixhobo kunye nezixhobo;cinga ukusebenzisa i-anti-static soldering iron ye-soldering manual.

C) Sebenzisa iibhokisi zokudluliselwa kwe-anti-static (qaphela ukuba iiplastiki eziqhelekileyo kunye nezikhongozelo zentsimbi azinazo iimpawu ezichasene ne-static).

D) Ngenxa yeempawu zokupakisha ze-sensor chip, kunqande ukusebenzisa iinkqubo ze-ultrasonic welding kwimveliso yemveliso yakho.

E) Yiba nononophelo ngexesha lokulungiswa ukuze uphephe ukuthintela ukungena komoya kwetshiphu.