iimveliso

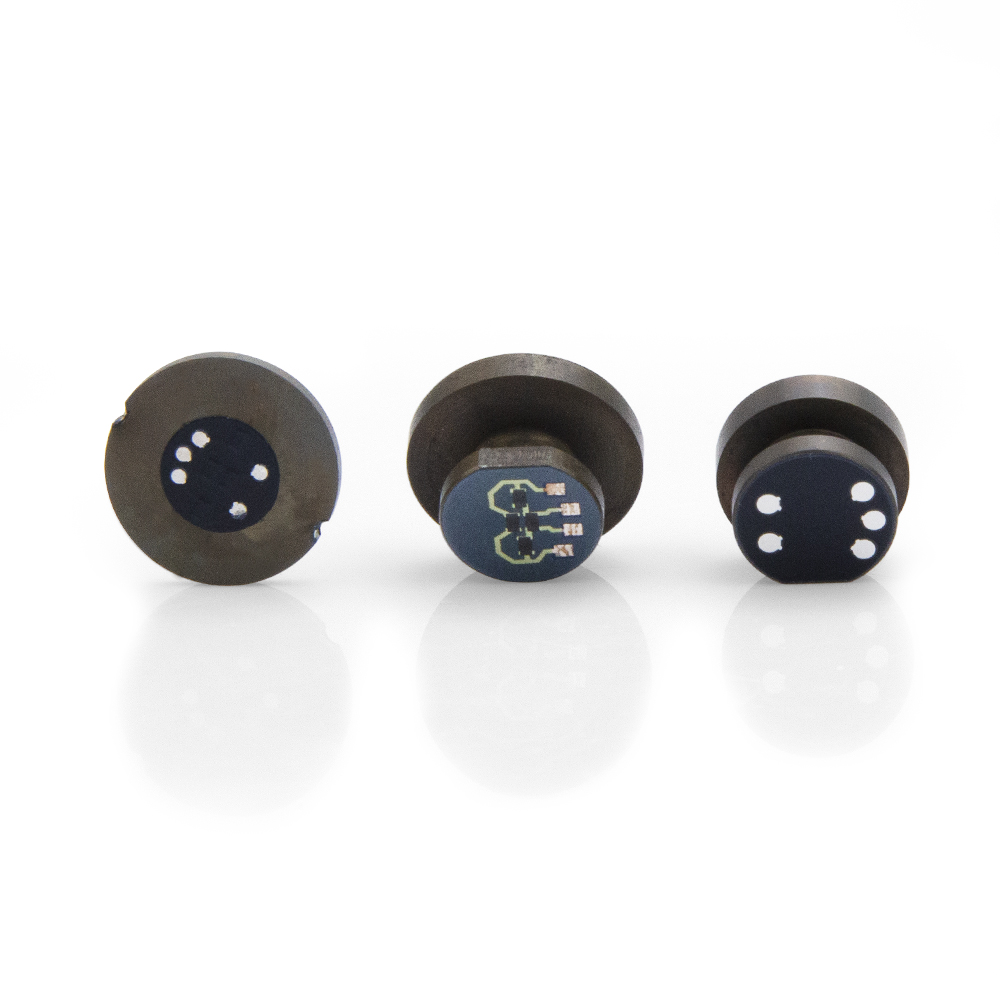

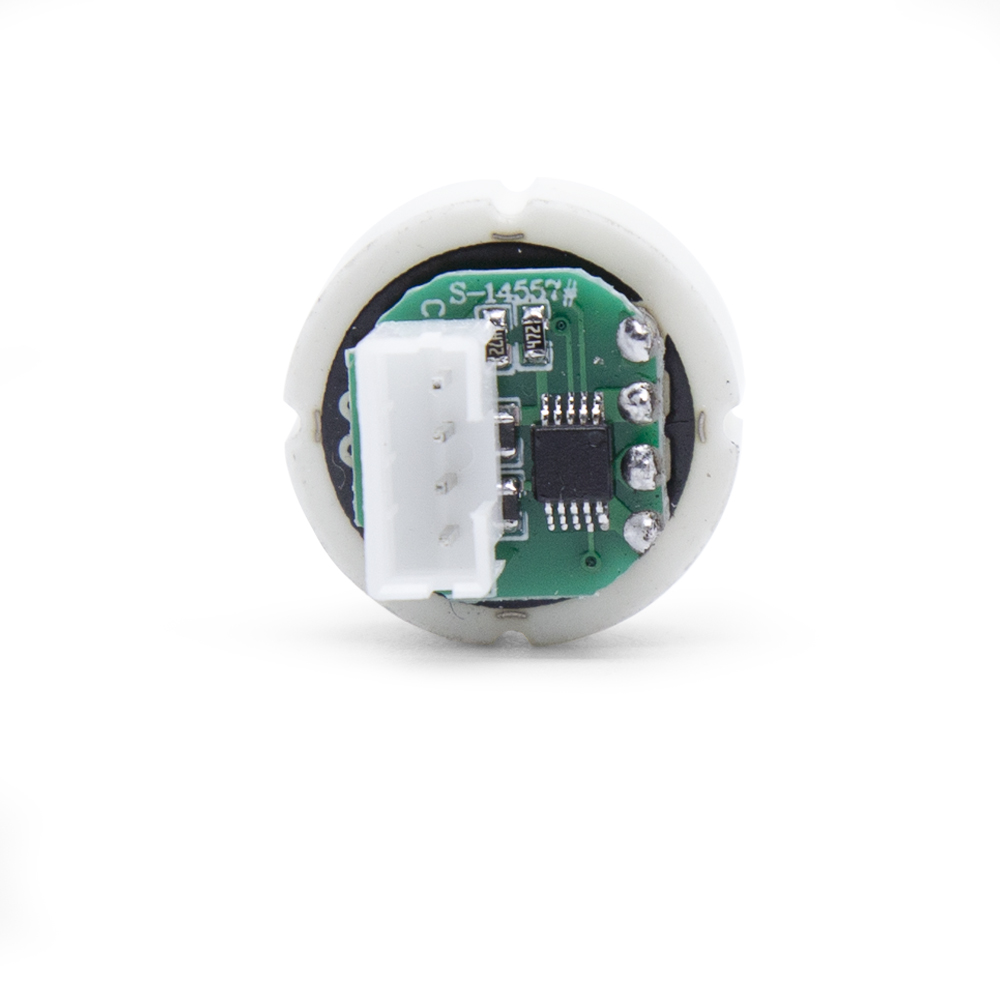

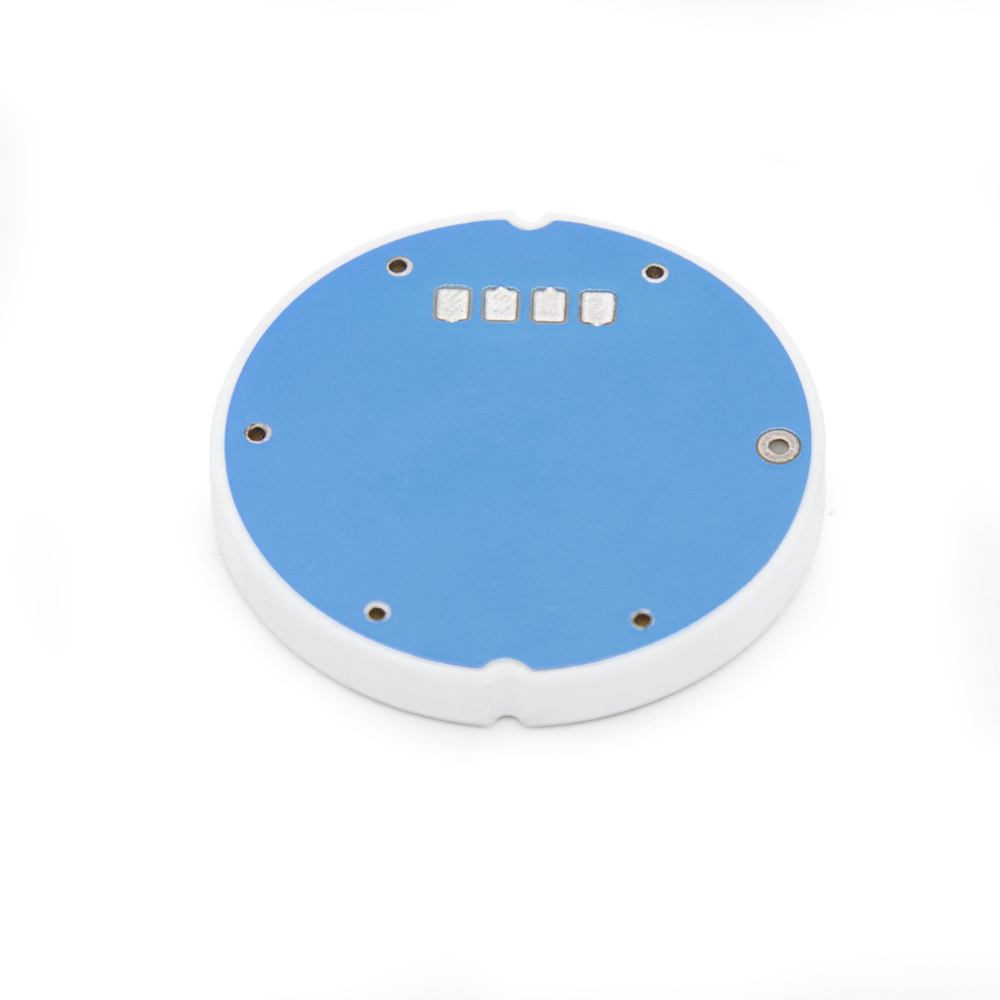

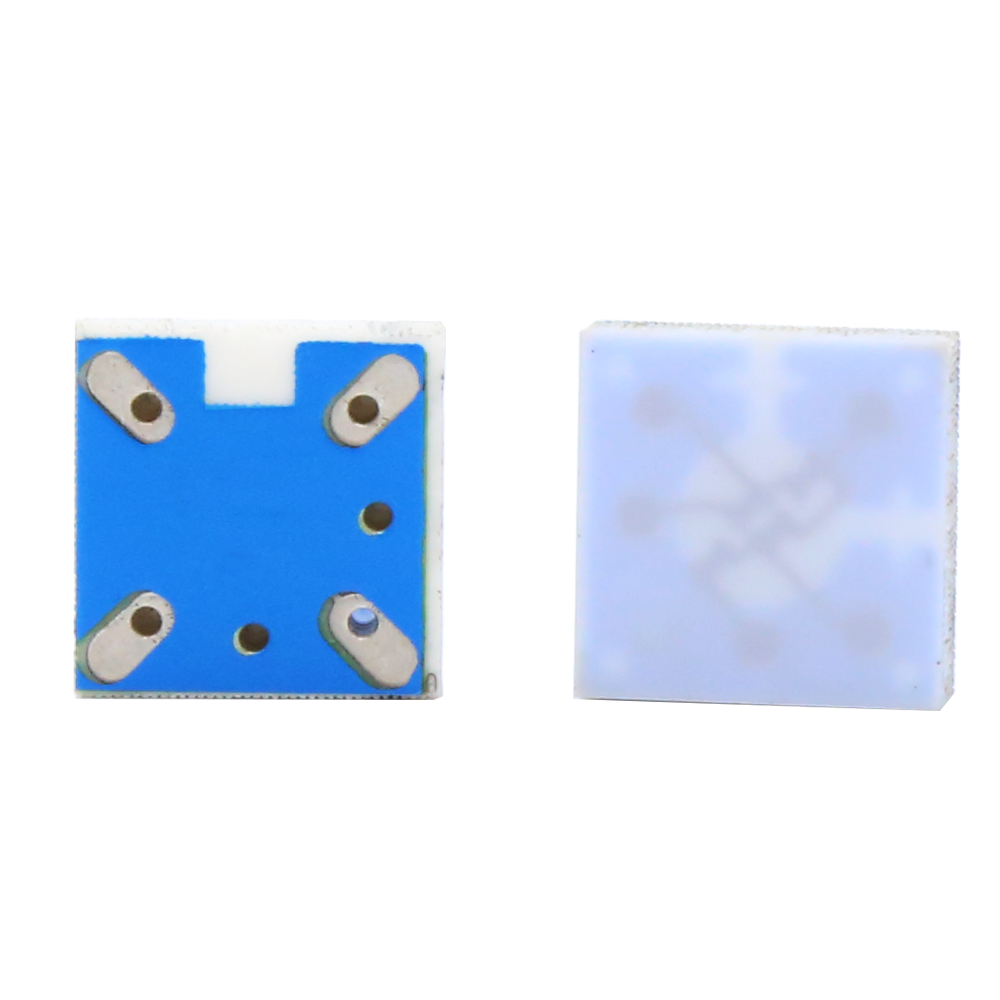

XDB100 iPiezoresistive Ceramic Pressure Sensor

Iimbonakalo

● Uzinzo olugqwesileyo lwexesha elide

● Imbuyekezo yobushushu esebenzayo

Usetyenziso oluqhelekileyo

● Ishishini

● I-valve, i-transmit, iikhemikhali, ubunjineli bepetrochemical, igeji yekliniki njl.njl.

Iiparamitha zobuGcisa

| Uluhlu loxinzelelo | 2 ~ 600 igeji yebha (ukhetho) | Ubungakanani | φ(18/13.5)×(6.35/3.5) mm |

| Uxinzelelo lokuqhuma | 1.15~3 amaxesha (uluhlu luyahluka) | Unikezelo lombane | 0-30 VDC (max) |

| Ukuphazamiseka kwendlela yebhulorho | 11 KQ±30% | Uluhlu olupheleleyo lwemveliso | ≥2 mV/V |

| Ubushushu bokusebenza | -40 ~+135℃ | Ubushushu bokugcina | -50 ~+150 ℃ |

| Ukuchaneka kukonke(umgca + hysteresis) | ≤±0,3% FS | Ukukhukuliseka kobushushu(zero & ubuntununtunu) | ≤±0.03% FS/℃ |

| Ukuzinza kwexesha elide | ≤± 0.2% FS/ngonyaka | Ukuphindaphinda | ≤± 0.2% FS |

| Zero offset | ≤± 0.2 mV/V | Ukumelana ne-insulation | ≥2 KV |

| Zero-point uzinzo lwexesha elide @20°C | ±0.25% FS | Ubuntu bezizalwane | 0~99% |

| Uqhagamshelwano oluthe ngqo kunye nemathiriyeli engamanzi | 96% Al2O3 | Ukusinda okushiyekile | ≤7g(eqhelekileyo) |

Amanqaku

1. Xa ufaka i-ceramic sensor core, kubalulekile ukugxila ekufakeni ukumiswa.Ulwakhiwo kufuneka lubandakanye indandatho yoxinzelelo olusisigxina ukunciphisa indawo ye-sensor core kunye nokuqinisekisa ukusabalalisa uxinzelelo.Oku kunceda ukunqanda ukuguquguquka kokunyuka koxinzelelo olunokubangelwa ngabasebenzi abahlukeneyo.

2. Ngaphambi kwe-welding, yenza uhlolo olubonakalayo lwe-sensor pad.Ukuba i-oxidation ikhona kumphezulu we-pad (uwujika ube mnyama), coca i-pad nge-eraser phambi kwe-welding.Ukungaphumeleli ukwenza oko kunokukhokelela ekuphuhliseni umqondiso ongemhle.

3. Xa udibanisa iingcingo ezikhokelayo, sebenzisa itafile yokufudumeza kunye nokulawula ukushisa okubekwe kwi-140-150 degrees.Intsimbi ye-soldering kufuneka ilawulwe malunga nama-400 degrees.I-flux esekelwe ngamanzi, i-rinse-free-free ingasetyenziselwa inaliti ye-welding, ngelixa i-paste ecocekileyo ye-flux inconywa kwi-wire welding.Amalungu e-solder kufuneka agudileyo kwaye angabi naburrs.Ukunciphisa ixesha lokudibanisa phakathi kwentsimbi ye-soldering kunye ne-pad, kwaye ugweme ukushiya isinyithi se-solder kwi-sensor pad ngaphezu kwemizuzwana ye-30.

4. Emva kwe-welding, ukuba kuyimfuneko, coca i-flux eseleyo phakathi kwamanqaku e-welding usebenzisa i-brush encinci kunye nomxube we-0.3 inxalenye ye-ethanol epheleleyo kunye ne-0.7 inxalenye yesicoci sebhodi yesekethe.Eli nyathelo linceda ukuthintela ukuguquguquka okushiyekileyo ekuveliseni i-parasitic capacitance ngenxa yokufuma, okunokuchaphazela ukuchaneka komqondiso wemveliso.

5. Ukuqhuba ukufumanisa umqondiso wemveliso kwi-sensor edibeneyo, ukuqinisekisa isignali yemveliso ezinzileyo.Ukuba ukutsiba kwedatha kwenzeka, inzwa kufuneka iphinde idityaniswe kwaye idityaniswe kwakhona emva kokudlula ubhaqo.

6. Ngaphambi kokulinganisa i-sensor post-assembly, kubalulekile ukubeka amacandelo adibeneyo ukuxinzelela ukuze ulungelelanise uxinzelelo lwendibano ngaphambi kokulinganisa umqondiso.

Ngokuqhelekileyo, ukuhamba ngebhayisikili ephezulu kunye neqondo eliphantsi kunokuqeshwa ukukhawulezisa ukulingana koxinzelelo lwecandelo emva kokwandiswa kunye nenkqubo yokunciphisa.Oku kunokufezekiswa ngokubeka amacandelo kuluhlu lobushushu -20℃ ukuya ku-80-100℃ okanye ubushushu begumbi ukuya kuma-80-100℃.Ixesha le-insulation kumanqaku aphezulu kunye namaqondo okushisa aphantsi kufuneka abe ubuncinane beeyure ze-4 ukuqinisekisa iziphumo ezilungileyo.Ukuba ixesha le-insulation lifutshane kakhulu, ukusebenza kwenkqubo kuya kuphazamiseka.Ubushushu benkqubo ethile kunye nexesha lokugquma linokumiselwa ngokulinga.

7. Gwema ukukrazula i-diaphragm ukukhusela umonakalo onokwenzeka kwisekethe yangaphakathi ye-ceramic sensor core, enokubangela ukusebenza okungazinzanga.

8. Yiba nononophelo ngexesha lokunyuswa ukunqanda naziphi na iimpembelelo zoomatshini ezinokuthi zibangele ukungasebenzi kakuhle kombindi weemvakalelo.

Nceda uqaphele ukuba ezi ngcebiso zingasentla ze-ceramic sensor assembly zikhethekileyo kwiinkqubo zenkampani yethu kwaye zisenokungasebenzi njengemigangatho yeenkqubo zemveliso yabathengi.

Ukuodola Ulwazi