Kwimilinganiselo yoxinzelelo, unokuqaphela ukuba iziphumo zokulinganisa azibonakalisi ngokukhawuleza utshintsho kuxinzelelo lwegalelo okanye zihambelana ngokupheleleyo xa uxinzelelo lubuyela kwimeko yalo yokuqala. Ngokomzekelo, xa usebenzisa isikali sokuhlambela ukulinganisa ubunzima, inzwa yesikali idinga ixesha lokuziva ngokuchanekileyo kunye nokuzinzisa ukufundwa kobunzima bakho. Iixesha lokuphendulaIsixhobo soluvo sikhokelela ekuguqukeni kwedatha yokuqala. Emva kokuba inzwa ilungelelanisa umthwalo kwaye igqibe ukucutshungulwa kwedatha, ukufundwa kuya kubonisa iziphumo ezizinzileyo.Oku akusiyo impazamo yenzwa kodwa luphawu oluqhelekileyo lwezixhobo ezininzi zokulinganisa i-elektroniki, ngakumbi xa kubandakanya ukusetyenzwa kwedatha yexesha langempela kunye nempumelelo ezinzileyo. Le nto ingabizwa ngokuba yi-sensor hysteresis.

Yintoni i-hysteresis kwiinzwa zoxinzelelo?

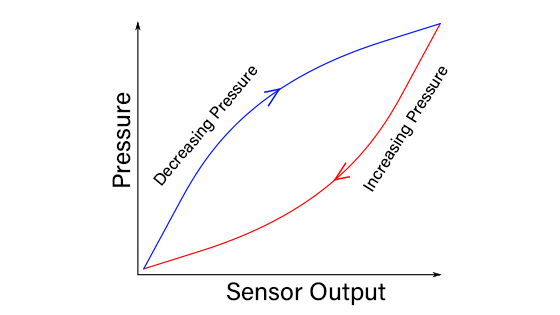

Isivamvoi-hysteresisibonakala xa kukho utshintsho kwigalelo (elifana neqondo lobushushu okanye uxinzelelo), kwaye isignali yemveliso ayilandeli ngokukhawuleza utshintsho lwegalelo, okanye xa igalelo libuyela kwimeko yalo yokuqala, isignali yemveliso ayibuyeli ngokupheleleyo kwimo yayo yokuqala. . Lo mcimbi unokubonwa kwigophe lophawu lwesixhobo soluvo, apho kukho ijiko elixegayo elimise okwelophu phakathi kwegalelo kunye nemveliso, kunomgca othe ngqo. Ngokukodwa, ukuba uqala ukwandisa igalelo kwixabiso elithile, imveliso yenzwa iya kwanda ngokufanelekileyo. Nangona kunjalo, xa igalelo liqala ukuhla libuyela kwindawo yokuqala, uya kufumanisa ukuba ixabiso lemveliso liphezulu kunexabiso lemveliso yoqobo ngexesha lenkqubo yokunciphisa, ukwenza iluphu okanyei-hysteresis loop. Oku kubonisa ukuba ngexesha lokunyuka kunye nokuncipha kwenkqubo, ixabiso legalelo elifanayo lihambelana namaxabiso amabini ahlukeneyo okuphumayo, oku kubonisa intuitive ye-hysteresis.

Umzobo ubonisa ubudlelwane phakathi kwemveliso kunye noxinzelelo olusetyenzisiweyo kwinzwa yoxinzelelo ngexesha lenkqubo yesicelo soxinzelelo, emelwe ngendlela ye-hysteresis curve. I-axis ethe tyaba imele isiphumo senzwa, kwaye i-axis ethe nkqo imele uxinzelelo olusetyenzisiweyo. Ijika elibomvu limele inkqubo apho i-sensor output inyuka ngokunyuka kwengcinezelo ngokuthe ngcembe, ibonisa indlela yokuphendula ukusuka kwi-low ukuya kwi-high pressure. Ijika elihlaza okwesibhakabhaka libonisa ukuba njengoko uxinzelelo olusetyenzisiweyo luqala ukuhla, i-sensor output iyancipha, ukusuka kuxinzelelo oluphezulu ukuya kwi-low, ebonisa ukusabela kwenzwa ngexesha lokukhulula uxinzelelo. Ummandla ophakathi kwee-curves ezimbini, i-hysteresis loop, ubonisa umehluko kwimveliso yenzwa kwinqanaba elifanayo loxinzelelo ngexesha lokulayisha kunye nokukhupha, ngokuqhelekileyo kubangelwa iipropati ezibonakalayo kunye nesakhiwo sangaphakathi se-sensor material.

Izizathu zoxinzelelo lweHysteresis

I-hysteresis phenomenon kwiabenzi boxinzeleloIphenjelelwa ikakhulu zizinto ezimbini eziphambili, ezinxibelelene ngokusondeleyo neempawu zomzimba kunye nendlela yokusebenza yenzwa:

- I-hysteresis ye-elastic ye-Material Nayiphi na into iya kungena kwinqanaba elithile le-elastic deformation xa iphantsi kwamandla angaphandle, ukuphendula ngokuthe ngqo kwezinto eziphathekayo kwimikhosi esetyenzisiweyo. Xa amandla angaphandle esusiwe, izinto eziphathekayo zizama ukubuyela kwimeko yazo yangaphambili. Nangona kunjalo, oku kubuyiselwa akuphelelanga ngenxa yokungafaniyo ngaphakathi kwesakhiwo sangaphakathi sezinto eziphathekayo kunye neenguqu ezincinci ezingenakuguqulwa kwi-microstructure yangaphakathi ngexesha lokulayisha ngokuphindaphindiweyo kunye nokukhulula. Oku kubangela i-lag kwimveliso yokuziphatha koomatshini ngexesha lokulayisha okuqhubekayo kunye neenkqubo zokukhuphela, ezaziwa ngokubai-elastic hysteresis. Lo mcimbi ubonakala ngokukodwa ekusetyenzisweni kweabenzi boxinzelelo, njengoko abenzi boluvo bahlala befuna ukulinganisa kwaye baphendule utshintsho loxinzelelo ngokuchanekileyo.

- I-Friction Kumacandelo omatshini we-sensor yoxinzelelo, ngakumbi ezo zibandakanya iindawo ezihambayo, ukungqubuzana akunakuphepheka. Le ngxabano inokuvela kubafowunelwa ngaphakathi kwenzwa, njengamanqaku oqhagamshelwano olulayidi, iibheringi, njl. uxinzelelo lwangempela. Xa uxinzelelo lukhutshwa, amandla afanayo okuxhatshazwa anokuthi athintele izakhiwo zangaphakathi ukuba ziyeke ngokukhawuleza, ngaloo ndlela zibonise i-hysteresis ngexesha lesigaba sokukhulula.

Ezi zinto zimbini zidibene zikhokelela kwi-hysteresis loop ebonwe kwi-sensors ngexesha lokulayishwa okuphindaphindiweyo kunye novavanyo lokukhulula, uphawu oluhlala luxhalabisa ngokukodwa kwizicelo apho ukuchaneka kunye nokuphindaphinda kufunwa kakhulu. Ukunciphisa impembelelo yale nto ye-hysteresis, ukuyila ngokucokisekileyo kunye nokukhethwa kwezinto eziphathekayo kwinzwa kubalulekile, kwaye i-algorithms yesofthiwe ingafuneka kwakhona ukuhlawulela le hysteresis kwizicelo.

I-hysteresis phenomenon kwiabenzi boxinzeleloiphenjelelwa zizinto ezahlukeneyo ezinxulumene ngqo neempawu zomzimba kunye neekhemikhali zenzwa kunye nendawo yokusebenza kwayo.

Ziziphi izinto ezikhokelela kwi-sensor hysteresis?

1. Iimpawu zezinto eziphathekayo

- Imodyuli elastiki: Imodyuli elastiki yemathiriyeli imisela inqanaba le-elastic deformation xa iphantsi kokunyanzeliswa. Izixhobo ezine-elastic modulus ephezulu zikhubaza ngaphantsi, kwaye zazoi-elastic hysteresisinokuba ngaphantsi.

- Umlinganiselo we-Poisson: Umlinganiselo we-Poisson uchaza umlinganiselo we-contract lateral ukuya kwi-longitudinal elongation kwi-material xa iphantsi kokunyanzeliswa, ekwachaphazela ukuziphatha kwezinto ngexesha lokulayisha kunye nokukhupha.

- Isakhiwo sangaphakathi: I-microstructure yezinto eziphathekayo, kubandakanywa isakhiwo se-crystal, iziphene, kunye nokubandakanywa, kuchaphazela ukuziphatha kwayo komatshini kunye neempawu ze-hysteresis.

2. Inkqubo yokuvelisa

- Ukuchaneka komatshini: Ukuchaneka kwecandelo le-sensor machining kuchaphazela ngokuthe ngqo ukusebenza kwayo. Amalungu anobuchwephesha obuphezulu afaneleka ngcono, anciphisa ukukhuhlana okongeziweyo kunye noxinzelelo loxinzelelo olubangelwa kukungafaneli kakuhle.

- Uburhabaxa bomphezulu: Umgangatho wonyango lomphezulu, njengoburhabaxa bomhlaba, buchaphazela ubungakanani bokungqubana, ngaloo ndlela buchaphazela isantya sokuphendula senzwa kunye ne-hysteresis.

- Utshintsho lobushushu luchaphazela iipropati ezibonakalayo zezinto eziphathekayo, ezifana ne-elastic modulus kunye ne-friction coefficient. Amaqondo obushushu aphezulu enza ukuba imathiriyeli ibe thambileyo, inciphisa i-elastic modulus kunye nokwandisa ukukhuhlana, ngaloo ndlela inyusa i-hysteresis. Ngakolunye uhlangothi, amaqondo obushushu aphantsi anokwenza izinto zibe nzima kwaye zibe brittle, ezichaphazela i-hysteresis ngeendlela ezahlukeneyo.

3. Ubushushu

- Utshintsho lobushushu luchaphazela iipropati ezibonakalayo zezinto eziphathekayo, ezifana ne-elastic modulus kunye ne-friction coefficient. Amaqondo obushushu aphezulu enza ukuba imathiriyeli ibe thambileyo, inciphisa i-elastic modulus kunye nokwandisa ukukhuhlana, ngaloo ndlela inyusa i-hysteresis. Ngakolunye uhlangothi, amaqondo obushushu aphantsi anokwenza izinto zibe nzima kwaye zibe brittle, ezichaphazela i-hysteresis ngeendlela ezahlukeneyo.

Imingcipheko

Ubukho be-hysteresis ngaphakathiabenzi boxinzelelokunokubangela iimpazamo zokulinganisa, ezichaphazela ukuchaneka kunye nokuthembeka kwenzwa. Kwizicelo ezifuna imilinganiselo yokuchaneka okuphezulu, njengokuchaneka kokulawulwa kwenkqubo yoshishino kunye nokubeka iliso kwizixhobo zonyango ezibalulekileyo, i-hysteresis inokukhokelela kwiimpazamo ezinkulu zokulinganisa kwaye ibangele ukuba yonke inkqubo yokulinganisa ingaphumeleli. Ke ngoko, ukuqonda kunye nokunciphisa impembelelo ye-hysteresis yinxalenye ephambili yokuqinisekisa ukusebenza ngokufanelekileyo nangokuchanekileyo.abenzi boxinzelelo.

Izisombululo zeHysteresis kwiiSensors zoxinzelelo:

Ukuqinisekisa ezona ziphumo zisezantsi ze-hysteresis kwiabenzi boxinzelelo, abavelisi bathathe amanyathelo aphambili amaninzi okwandisa ukusebenza koluvo:

- Ukukhethwa kwezinto eziphathekayo: Ukukhethwa kwezinto eziphathekayo kudlala indima ebalulekileyo kwi-hysteresis. Ke ngoko, abavelisi bakhetha ngononophelo izinto eziphambili ezisetyenziselwa ukwakhiwa kwenzwa, ezinje ngee-diaphragms, izitywina, kunye nokuzalisa ulwelo, ukuqinisekisa ukuba babonisa i-hysteresis encinci phantsi kweemeko ezahlukeneyo zokusebenza.

- Ukulungiswa koyilo: Ngokuphucula uyilo lolwakhiwo lwezinzwa, ezinje ngemilo, ubungakanani, kunye nobukhulu be-diaphragms, kunye nokuphucula iindlela zokutywina, abavelisi banokunciphisa ngokufanelekileyo i-hysteresis ebangelwa kukungqubana, ukungqubana okungatshintshiyo, kunye nokuguqulwa kwezinto.

- Unyango lokuguga: Izinzwa ezisandula ukwenziwa zingabonisa i-hysteresis ebalulekileyo yokuqala. Ngokusebenzisaunyango lokugugakunye neenkqubo ezithile zokuvavanya, izixhobo zinokukhawuleziswa ukuzinzisa kunye nokulungelelanisa, ngaloo ndlela ukunciphisa le hysteresis yokuqala. Umfanekiso ongezantsi ubonisa iXDB305kuqhubekaunyango lokuguga.

- Ukulawulwa kwemveliso engqongqo: Ngokulawula ngokungqongqo ukunyamezela kunye nomgangatho ngexesha lenkqubo yokuvelisa, abavelisi baqinisekisa ukuhambelana kwenzwa nganye kunye nokunciphisa impembelelo yeenguqu zemveliso kwi-hysteresis.

- Ulungelelwaniso oluphezulu kunye nembuyekezo: Abanye abavelisi basebenzisa itekhnoloji yembuyekezo yedijithali ephezulu kunye neendlela zokulinganisa amanqaku amaninzi ukwenza imodeli echanekileyo kunye nokulungisa i-hysteresis kwiziphumo zoluvo.

- Uvavanyo lokusebenza kunye nokuhlelwa: Zonke izinzwa zivavanywa ngokucokisekileyo ukuvavanya iimpawu zazo ze-hysteresis. Ngokusekwe kwiziphumo zovavanyo, abenzi boluvo bahlelwa ukuze kuqinisekiswe ukuba ziimveliso kuphela ezidibana nemigangatho ethile ye-hysteresis ekhutshwa kwintengiso.

- Uvavanyo olukhawulezileyo lobomi: Ukuqinisekisa ukuzinza kokusebenza kweenzwa kulo lonke ixesha lokuphila kwabo elilindelekileyo, abavelisi baqhuba ukuguga okukhawulezileyo kunye novavanyo lobomi kwiisampulu zokuqinisekisa ukuba i-hysteresis ihlala ngaphakathi kwemida eyamkelekileyo.

La manyathelo abanzi anceda abavelisi ukulawula ngokufanelekileyo kunye nokunciphisa i-hysteresis phenomenon kwiabenzi boxinzelelo, ukuqinisekisa ukuba abenzi boluvo bahlangabezana nokuchaneka okuphezulu kunye neemfuno zokuthembeka kwizicelo zangempela.

Ixesha lokuposa: May-09-2024