1. Intshayelelo

Iinkqubo zeHydrauliczibuchwephesha obungundoqo kushishino lwanamhlanje, oluyimfuneko ekugqithiseni nasekulawuleni amandla koomatshini, ukuvelisa, kunye neenkqubo zamandla ukuqinisekisa ukusebenza ngokufanelekileyo kwezixhobo zoomatshini. Ngaphakathi kwezi nkqubo, ii-sensor ze-high-performance sensors zidlala indima ebalulekileyo, njengoko kufuneka zibonelele ngokuchanekileyo kwaye zizinzileyo zokubeka iliso loxinzelelo kwiindawo ezinoxinzelelo oluphezulu kunye neendawo ezinzima. Njengoko iimfuno zemizi-mveliso ziqhubeka nokukhula, itekhnoloji ye-sensor iye yavela, kunye ne-ceramic kunye ne-glass microfused materials eziphuma njengezinto ezimbini eziphambili ze-sensor core.

Izixhobo zeCeramic zidume ngamandla azo aphezulu, ukumelana nobushushu, kunye nokumelana nokugqwala, ukugcina ukusebenza okugqwesileyo phantsi kweemeko ezinzima. Zisetyenziswa ngokubanzi ekufuneni izicelo zamashishini. Kwelinye icala, itekhnoloji yeglasi ye-microfused isebenzisa ubushushu obuphezulu beglasi umgubo ukwenza i-seamless, i-O-ring-free, izakhiwo ezitywinwe kakhulu, ziyenza ifaneleke ngakumbi ukuthintela ukuvuza kweoyile kwiinkqubo zehydraulic. Eli nqaku liza kuthelekisa ukusebenza kwezi zinto zimbini kwizicelo zeoyile ye-hydraulic, iphonononga iingenelo zabo kunye nokungonakali ukunceda abafundi benze olona khetho lulungileyo kwiimeko ezahlukeneyo zesicelo.

2. IiMfuno eziSisiseko zeeSensors kwii-Hydraulic Systems

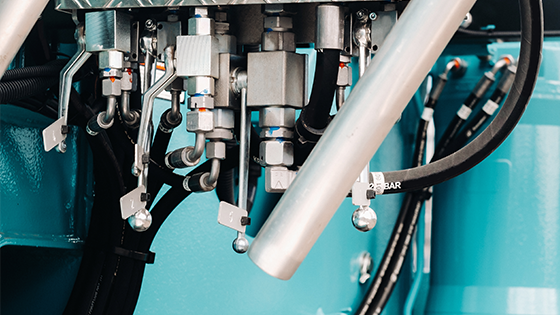

Iinzwa zoxinzelelo kwiinkqubo ze-hydraulic kufuneka zihlangabezane neemfuno eziphambili zokuqinisekisa ukhuseleko lwenkqubo kunye nokusebenza kakuhle. Ekuqaleni,ukumelana noxinzeleloIbalulekile kakhulu kuba iisistim zehydraulic zihlala zisebenza phantsi koxinzelelo oluphezulu kakhulu. Iinzwa kufuneka zisebenze ngokuthembekileyo phantsi kwezi meko zoxinzelelo oluphezulu, ukuthintela ukuthotywa kokusebenza okanye ukungaphumeleli ngenxa yokuguquguquka koxinzelelo.

Isibini,ukutywinwa kunye nokuthintela ukuvuza kweolizibaluleke kakhulu kwi-oyile ye-hydraulic. Ukuvuza kweoyile akunciphisi ukusebenza kakuhle kwenkqubo kuphela kodwa kunokubangela umonakalo wesixhobo okanye iingozi zokhuseleko. Ke ngoko, abenzi boluvo kufuneka babe nesakhono sokutywina esisemagqabini ukunqanda ngokufanelekileyo ukuvuza kweoyile yehydraulic, ukuqinisekisa ukusebenza okuzinzileyo kwenkqubo yexesha elide.

Ekugqibeleni,ukuzinza kwexesha elide kunye nokuqinazikwayimfuneko ebalulekileyo kwizivamvo kwiisistim zehydraulic. Ii-Sensors kufuneka zikwazi ukusebenza ngokuthembekileyo kwixesha elide kwindawo yoxinzelelo oluphezulu, ubushushu obuphezulu ngaphandle kokulahlekelwa ukuchaneka komlinganiselo okanye ukusilela ngenxa yeemeko ezinzima. Ezi mfuno ezisisiseko zinquma ukusebenza kwezinto ezahlukeneyo zenzwa kwiinkqubo ze-hydraulic kwaye zibonelela ngesiseko sokukhethwa kwezinto ezilandelayo.

3. Izinto zeCeramic kwi-Hydraulic Oil Applications

Iimpawu zeMathiriyeli: I-Ceramic yinto ephezulu, i-heat-resistant, kunye ne-corrosion-resistant-resistant material egcina ukusebenza okuzinzileyo phantsi kweemeko ezinzima. Ezi mpawu zenza i-ceramic cores ngokukhethekileyo ilungele ukusetyenziswa kwimidiya yeoli ye-hydraulic, apho kufuneka umsebenzi ozinzileyo wexesha elide.

Iingenelo: Iingqungquthela ze-Ceramic zisebenza ngokugqithiseleyo phantsi kweemeko eziphezulu kunye neemeko ze-vacuum, ngokukodwa ngokubhekiselele kuzinzo lwexesha elide kwiindawo ezinzima. Ngenxa yokuqina kunye nokuqina kwezixhobo ze-ceramic, i-ceramic cores inokumelana nokuguquguquka okukhulu koxinzelelo ngaphandle kokuguqulwa okanye ukungaphumeleli. Ukongeza, ii-ceramic cores zibonelela ngemilinganiselo echanekileyo kunye nezinzile nakwimeko yevacuum, ibanika umda ngaphezu kwezinye izinto kwiinkqubo ezithile ezikhethekileyo zehydraulic. I-XIDIBEI'sXDB305 seriesIsebenzisa ezi mpawu zemathiriyeli ye-ceramic, iyenza isebenze ngokubanzi kwiindawo ezintsonkothileyo zemizi-mveliso.

Iingxaki: Ngaphandle kokusebenza kwabo okugqwesileyo kubushushu obuphezulu kunye noxinzelelo oluphezulu, i-ceramic cores ayinakutywinwa ngokunjalo kwimithombo yeoyile ye-hydraulic njengeglasi ye-microfused cores. Oku kuqala kungenxa yokuba izixhobo ze-ceramic zinobunzima, zenza kube nzima ukufezekisa izitywina eziqinileyo ezinokubonelela ngeteknoloji yeglasi. Oku kuthetha ukuba kwezinye iimeko, ii-ceramic cores zinokubeka umngcipheko wokuvuza kweoyile ye-hydraulic, ngakumbi emva kokusetyenziswa ixesha elide xa ukutywinwa kokusebenza kunokuthoba. Le ntsilelo yenza ukuba ii-cores ze-ceramic zingabinakho ukulungela usetyenziso oluneemfuno zokutywinwa eziphezulu kakhulu xa kuthelekiswa ne-glass microfused cores. Ukongeza, ii-ceramic cores zifanelekile ngakumbi kwiindawo ezinoxinzelelo oluphantsi(≤600 ibha)kwaye ayifanelekanga kwiimeko zoxinzelelo oluphezulu.

4. Izinto zeGlass Microfused kwi-Hydraulic Oil Applications

Iimpawu zeMathiriyeli: Itekhnoloji ye-Glass microfused yinkqubo esebenzisa i-powder yeglasi ephezulu yokushisa ukwenza isakhiwo esingenamthungo kunye nesitywinwe kakhulu. Le teknoloji ifanelekile ngokukodwa kwimidiya yeoli ye-hydraulic kuba ithintela ngokufanelekileyo ukuvuza kwamanzi. Olu phawu lweglasi ye-microfused cores ibenza basebenze kakhulu kwizicelo ezifuna iqondo eliphezulu lokutywinwa, ngakumbi kwiinkqubo zoxinzelelo oluphezulu lwe-hydraulic.

Iingenelo: Eyona nzuzo iphambili yeglasi microfused cores kwi hydraulic oyile media kubuchule babo bokutywina obugqwesileyo. Ukungabikho kwe-O-rings kuphelisa iingozi zokuvuza ezinokubakho ezinxulumene neendlela zokutywinwa zendabuko, okwenza i-glass microfused cores isebenze ngokukodwa ekuthinteleni ukuvuza kweoli. I-XIDIBEI'sXDB317 series, ngokusekelwe kule teknoloji, inokugcina ingqibelelo yokutywinwa kwixesha elide kwiinkqubo zeoli ye-hydraulic, ukunciphisa ukusilela kwenkqubo ngenxa yokuvuza. Olu phawu lubenza lube lolona khetho lufanelekileyo lokuthintela ukuvuza kweoyile kwiinkqubo zamanzi.

Iingxaki: Nangona kunjalo, ii-cores zeglasi ezifakwe kwi-microfused zinemida ethile xa ujongana neendawo zevacuum. Ngenxa yoyilo kunye neempawu eziphathekayo, i-glass microfused cores ayikwazi ukubonelela ngezinga elifanayo lokuzinza kunye nokuchaneka kwiimeko ze-vacuum njenge-ceramic cores. Oku kuthintela ukusetyenziswa kwazo kwezinye iinkqubo ezikhethekileyo, ezifana neenkqubo ezintsonkothileyo zehydraulic ezifuna ukujongana noxinzelelo olulungileyo nolubi. Kwezi meko, iglasi ye-microfused cores ayinakuhlangabezana nazo zonke iimfuno zokulinganisa.

Ngokwenza uhlalutyo olucacileyo lwezicelo zezixhobo ezimbini kwimidiya yeoli ye-hydraulic, abafundi banokuqonda ngcono iimeko zabo zesicelo kunye neempawu zokusebenza, ukubonelela ngenkxaso eqinile yokukhetha itekhnoloji ye-sensor efanelekileyo.

5. Uhlalutyo lokuthelekisa kunye neemeko zeSicelo

Uhlalutyo lokuthelekisa: Kwimithombo ye-oyile ye-hydraulic, i-ceramic kunye ne-glass microfused cores nganye inamandla ahlukeneyo kunye nobuthathaka. I-Ceramic cores igqwesa ukunyanzeliswa koxinzelelo kunye nokuzinza kwexesha elide kwiindawo ezigqithiseleyo. Basebenza ngokukodwa phantsi kweemeko ze-vacuum kunye nobushushu obuphezulu, ukugcina ukuchaneka komlinganiselo ophezulu kunye nokumelana nokuphazamiseka kwangaphandle kokusingqongileyo. Nangona kunjalo, ngenxa yeempawu zezinto eziphathekayo, ii-ceramic cores zinokungatywinwa ngokufanelekileyo njengeglasi ye-microfused cores, enokuthi ikhokelele kwimiba yokuvuza kwi-oyile ye-hydraulic. Ngoko ke, isishwankathelo, ii-ceramic cores zifanelekile kwizicelo zoxinzelelo oluphantsi(≤600 ibha), ngelixa iimeko zoxinzelelo oluphezulu(ukuya kuthi ga kwi-3500 bar), i-glass microfused sensors iyacetyiswa.

Ngokwahlukileyo koko, ukomelela kweglasi ye-microfused cores kusekukwazini kwabo ukutywina okuphezulu, kubenza basebenze ngakumbi ekuthinteleni ukuvuza kweoyile yehydraulic. Uyilo lwe-O-ring-free aluphuculi kuphela ukuthembeka okupheleleyo kwenzwa kodwa kwakhona kunciphisa ukusilela okunokwenzeka ngenxa yokuthotywa kwetywina. Nangona kunjalo, iicores zeglasi ezifakwe kwiglasi zibuthathaka ngokwemeko yendawo yokufunxa kwaye azikwazi ukunika uzinzo olufanayo kwimilinganiselo njengee-ceramic cores.

Iingcebiso zemeko yeSicelo: Xa ukhetha i-sensor efanelekileyo, kubalulekile ukulinganisa iimfuno ezithile zesicelo. Ukuba inkqubo ye-hydraulic idinga ukutywinwa okuphezulu kunye nokuthintela ukuvuza kweoli, i-glass microfused cores iyona nto ikhethekileyo, ngokukodwa kwiindawo ezixinzelelekileyo kunye neenkqubo ezifuna ukutywinwa okuzinzileyo kwexesha elide, ezifana nezikhululo zokupompa kunye neenkqubo zokunyanga amanzi. Ngakolunye uhlangothi, kwiinkqubo ezifuna ukujongana noxinzelelo olulungileyo kunye nolubi okanye ukusebenza phantsi kobushushu obugqithisileyo kunye neemeko zoxinzelelo, i-ceramic cores inokufaneleka ngakumbi, inikezela ukuchaneka komlinganiselo ophezulu kunye nokuzinza phantsi kwezi meko zinzima.

6. Isiphelo

Ukuqukumbela, i-ceramic kunye ne-glass microfused cores nganye ineenzuzo zayo ezizodwa kunye nokusetyenziswa okufanelekileyo. I-Ceramic cores, kunye nokumelana noxinzelelo olugqwesileyo kunye nokuzinza kwiindawo ezigqithiseleyo, zisebenza ngokugqwesileyo kwiinkqubo ezifuna ukuphathwa koxinzelelo olunzima. Ngokwahlukileyo koko, ii-cores zeglasi ezine-microfused, kunye nokutywinwa kwazo okuphezulu kunye nokuthintela ukuvuza kweoyile, zilawula kwiinkqubo zehydraulic ezifuna ingqibelelo yokutywinwa okuphezulu.

Ukukhetha imathiriyeli yenzwa efanelekileyo ibalulekile ekuqinisekiseni ubomi obude kunye nokuthembeka okuphezulu kweenkqubo zehydraulic. Ngokukhetha iteknoloji ye-sensor efanelekileyo kakhulu esekelwe kwiimfuno ezithile zenkqubo, kunokwenzeka ukuba kuphuculwe ukusebenza kakuhle kwenkqubo, ukunciphisa umngcipheko wokungaphumeleli, kunye nokuqinisekisa ukusebenza okukhuselekileyo kunye nokuzinza phantsi kweemeko ezahlukeneyo. Le ndlela ayiphuculi nje ukusebenza kakuhle kwemveliso kodwa ikwanciphisa iindleko zokuyigcina kwaye yandisa ubomi besixhobo.

Ixesha lokuposa: Aug-28-2024